Hay is for horses; straw is for houses,

”

or so says Maurice Bennett, a

”

de facto director

”

of the California Straw Bale Association.

The Angel’s Camp, Calif. resident and his wife, Joy, have lived

in a home made of straw since the 1990s, but before you dismiss him

and begin picturing the three little piggies, know this: his straw

bale home looks no different than the timber construction you may

call your own, but it’s probably a whole lot more

Earth-friendly.

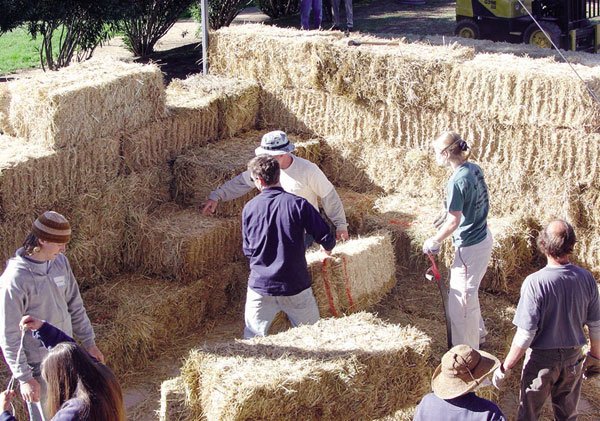

“Hay is for horses; straw is for houses,” or so says Maurice Bennett, a “de facto director” of the California Straw Bale Association.

The Angel’s Camp, Calif. resident and his wife, Joy, have lived in a home made of straw since the 1990s, but before you dismiss him and begin picturing the three little piggies, know this: his straw bale home looks no different than the timber construction you may call your own, but it’s probably a whole lot more Earth-friendly.

Alternative homes – whether made of straw, rammed earth or poured concrete – are not only different in their construction, they may also save home owners money in the long-term by cutting down on heat, cooling and electrical costs. And by using renewable resources coupled with environmentally sound tactics, these homes are reducing the destruction of more limited resources while keeping the production of waste and greenhouse gasses to a minimum.

Straw homes like Bennett’s – whose plastered, 2-foot-thick rice straw walls are reminiscent of an old monastery – hold incredible insulation value, he said.

Straw homes have nearly twice the insulating power of timber homes, he said.

The homes also perform well when faced with earthquakes and fires, said structural engineer and environmentalist Bruce King. Instead of burning like wooden-frame homes, exposed bales only smolder since they are too closely packed to burn efficiently, according to King’s Web site, EcoBuildNetwork.org.

“We received a quarter-million-dollar grant to study them from the state,” said King, who is director of the Ecological Building Network and founder of Green Building Press. “The only thing to really worry about is moisture, because mold will grow anywhere that’s warm and dark.”

Still, straw bale homes, when sealed properly with plaster or a variety of other coatings, can last for decades. Some in Nebraska have stood for more than 100 years, according to Bennett, who said that a turnkey bale home usually costs about 10 to 15 percent more than a regular house if the owners don’t help build it.

It’s similar to the costs faced by other green builders. A 1,500-square-foot earth-dome house, which is built into the ground or into a hillside to take advantage of the earth’s relatively constant temperatures, will cost prospective owners $120,000 to $200,000 to construct, excluding land prices, said Jay Scafe, manager of the building company Terra-Dome in Grain Valley, Mont. The cost is mostly due to the low demand for such homes, which may require specialty builders and significant engineering work, he said.

“You’re going to have safety advantages as far as from tornadoes, hurricanes and fire, and you’re going to have less maintenance because less of the house is exposed to the elements,” said Scafe. “We’ve had homes in Alaska go through a 7.5 earthquake and have no damage, but the hardest part about building them is getting financing.”

Most home loans are, at least in part, based on information culled from the values of comparable properties in the area, but since earthen homes are so far-flung, they’re not as likely to return any matches, said Scafe. The homes remain less popular in the United States, he believes, because they do not lend themselves to sub-division style building either. Most owners of subterranean homes have a substantial amount of acreage on which to build, though homes can be created on city-sized lots.

For easier access to financing and building permits, residents can also turn to more common materials with a green flair.

Turko Semmes, president of Semmes & Company Builders in Atascadero, Calif., offers home builders an alternative to traditional wood-frame construction with insulated concrete forms – a hollow pairing of Styrofoam that is filled with cement, providing stability and insulation in one.

“It’s kind of like giant Legos for adults,” said Semmes. “Anything with thermal mass – the ability to store temperature – stays at a relatively stable temperature. Caves are like that. They can absorb almost any amount of heat and stay the same temperature, and concrete can do that, too.”

The process is greener, Semmes said, because it relies on abundant resources like the sand and gravel used in concrete, rather than wood that must grow for years in order to produce the timber needed for construction.

“You also end up with something that’s not quite the same as frame construction,” said Semmes. “The walls in an insulated concrete-form home are about 12 inches thick, and straw bale is about 2 feet thick, so they become a visual element.”

Even with concrete, though, home owners can do more for the environment, according to King, who released his latest book, “Making Better Concrete,” this month.

According to King, concrete is the most-used building material on Earth. Were all the concrete poured in 2004 dumped in one spot, it would cover San Francisco in a solid slab 130 feet deep, he said.

“One of the only problems with concrete is that it is mixed with Portland cement,” said King. “About 8 percent of greenhouse gasses come from Portland cement, but there are quite a few alternatives.”

The most readily available alternative to Portland cement is something called fly ash, which is the ash produced by coal-powered electricity plants, the source of about half the nation’s power.

“We generate lots and lots of fly ash all over the world, and it turns out that if you tried to design something to act like Portland cement, it would look almost exactly like fly ash,” said King. “We can make better, more friendly products with the materials we have. We just have to look.”

For more information on alternative construction, visit King’s Web site, www.EcoBuildNetwork.org, or any of the following:

www.SemmesCo.com

www.StrawBuilding.org

www.Terra-Dome.com

www.GreenHomeGuide.com

www.PathToFreedom.com/

reading/shelter.shtml